Virtual reality is the new reality at Vale with the adoption of engaged learning experiences for pre-operational circle check training

Our "strategic partnership" with Vale, one of the world's top mining companies, aims to deliver new interactive and experiential training technology tools for pre-operational circle check training. This virtual reality educational tool allows Vale miners to strengthen their skills in performing work safely and productively.

Pulling mobile equipment from production to do training is not always easy or opportune, and sometimes equipment needs to be returned to production work before enough training can be done. Through our collaboration with Vale's Learning and Development department, we have created a new application program to train workers before they get underground at the mine site. VR is not intended to replace hands on training in the field, but to add to an already established learning environment. These new methods help to deliver training more efficiently and increase worker proficiency.

Instructor Powered Training Tool-set

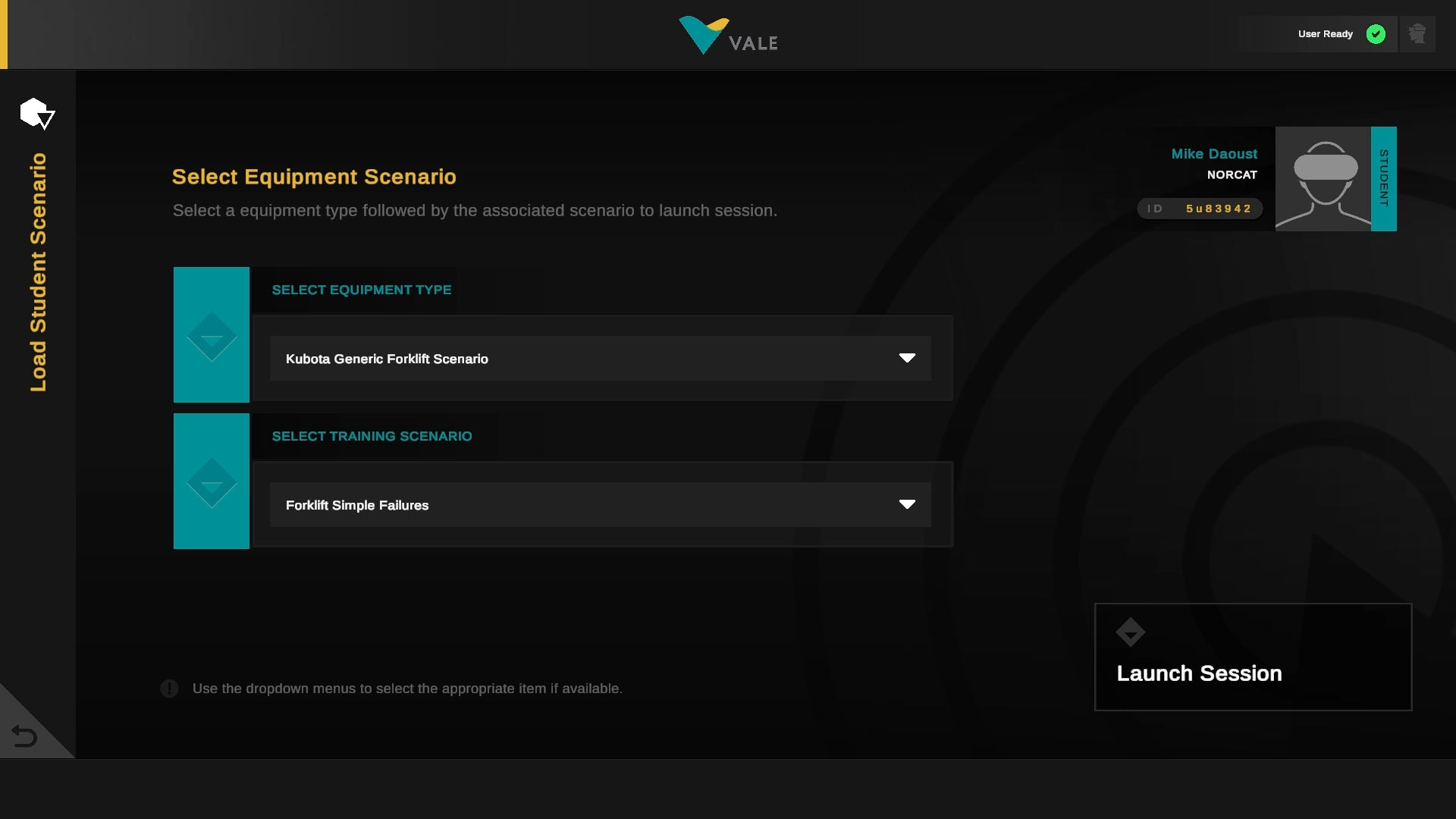

The training tool allows instructors the ability to place their student in a Virtual Reality environment. There, they will be taken to an underground simulation in which they are tasked to perform pre-operational circle checks, and identify any potential maintenance concerns.

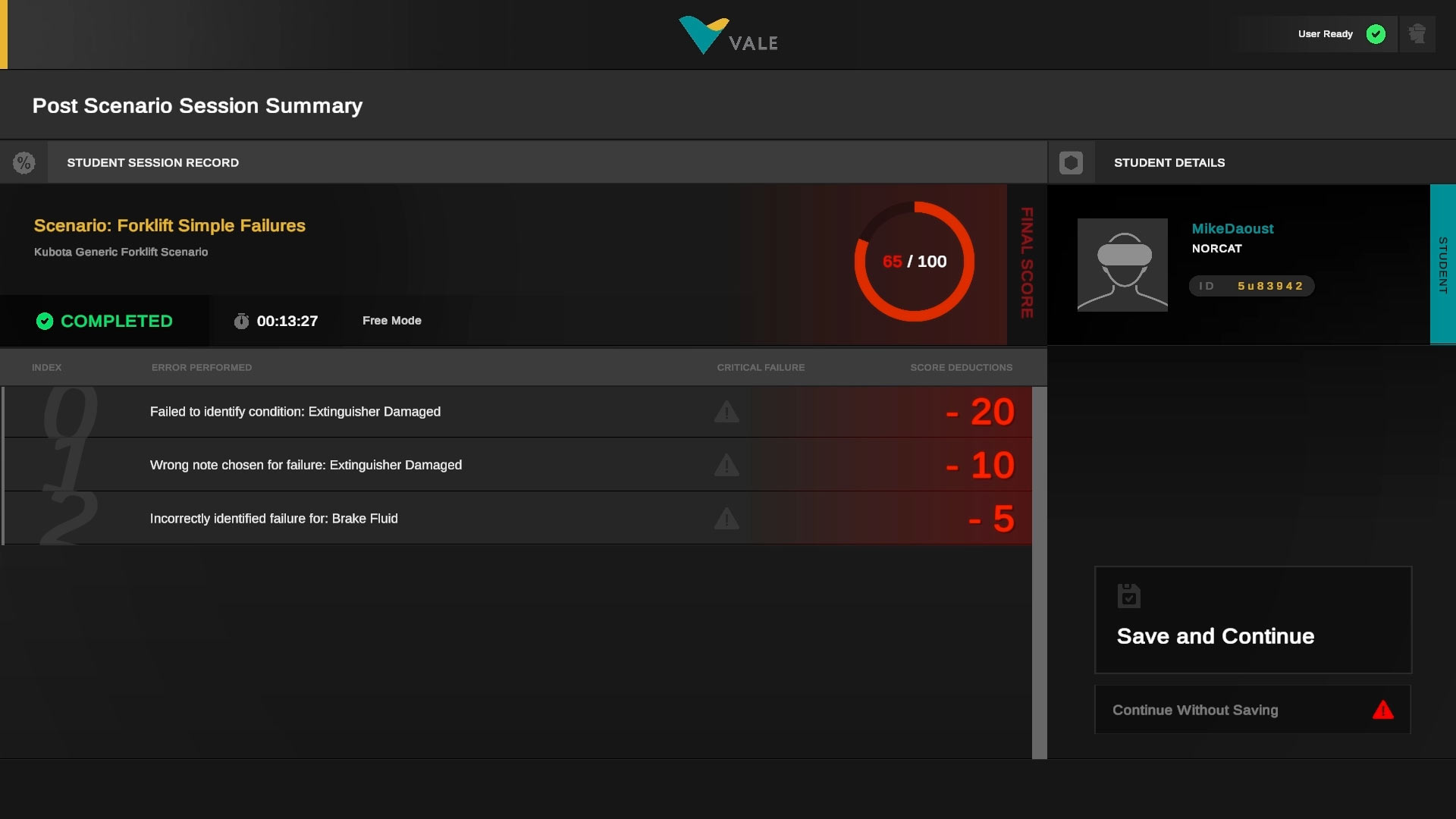

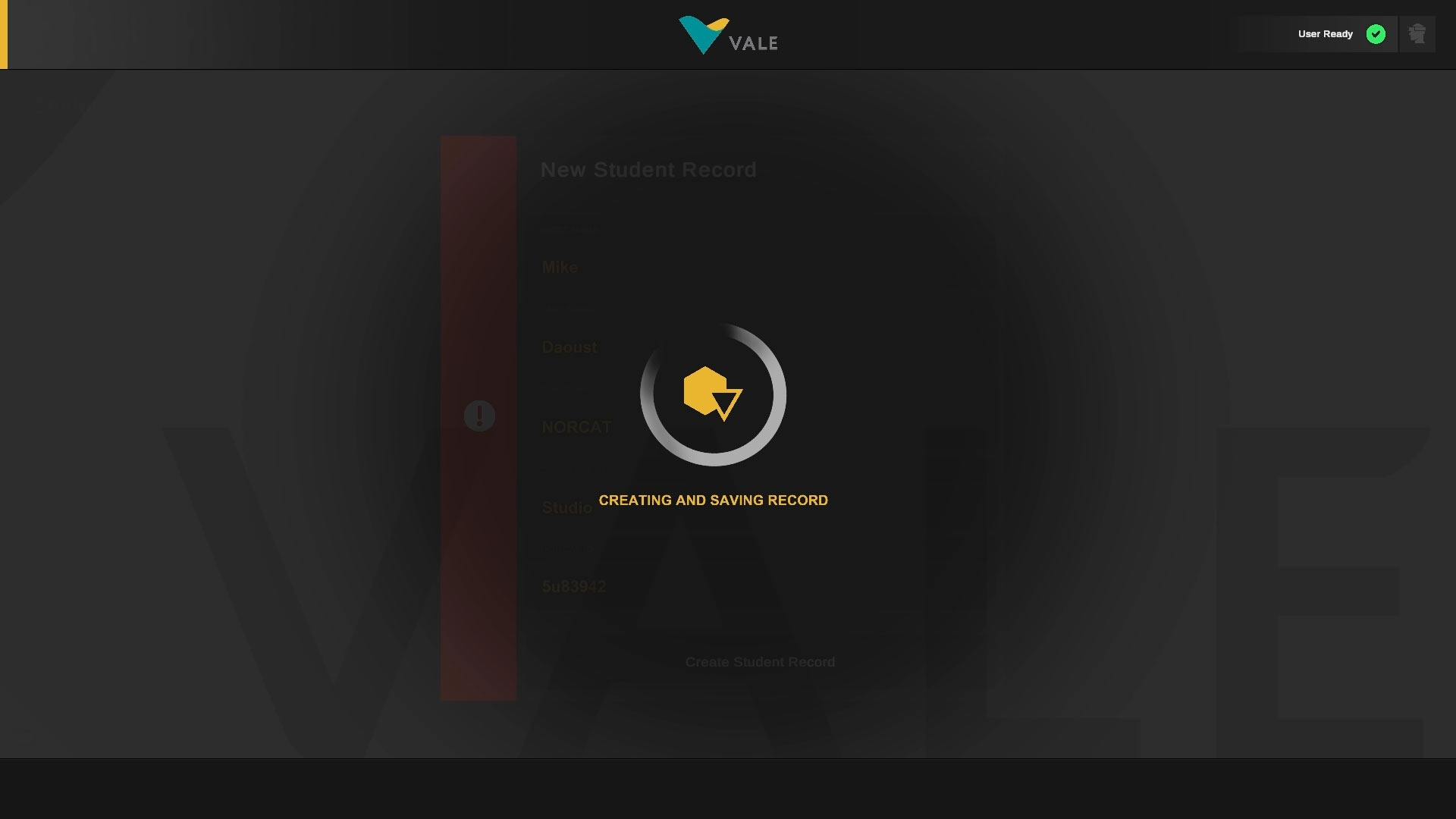

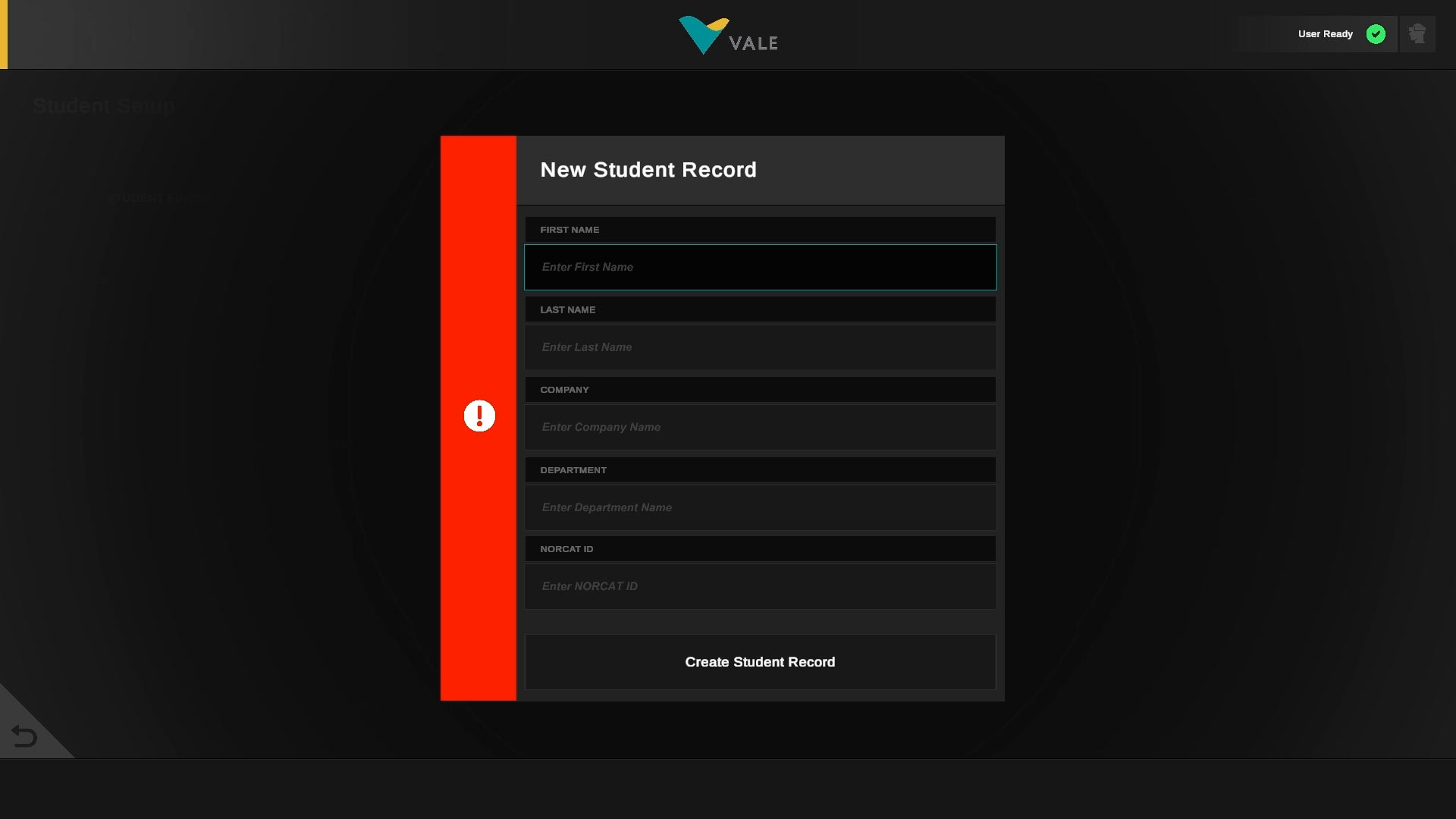

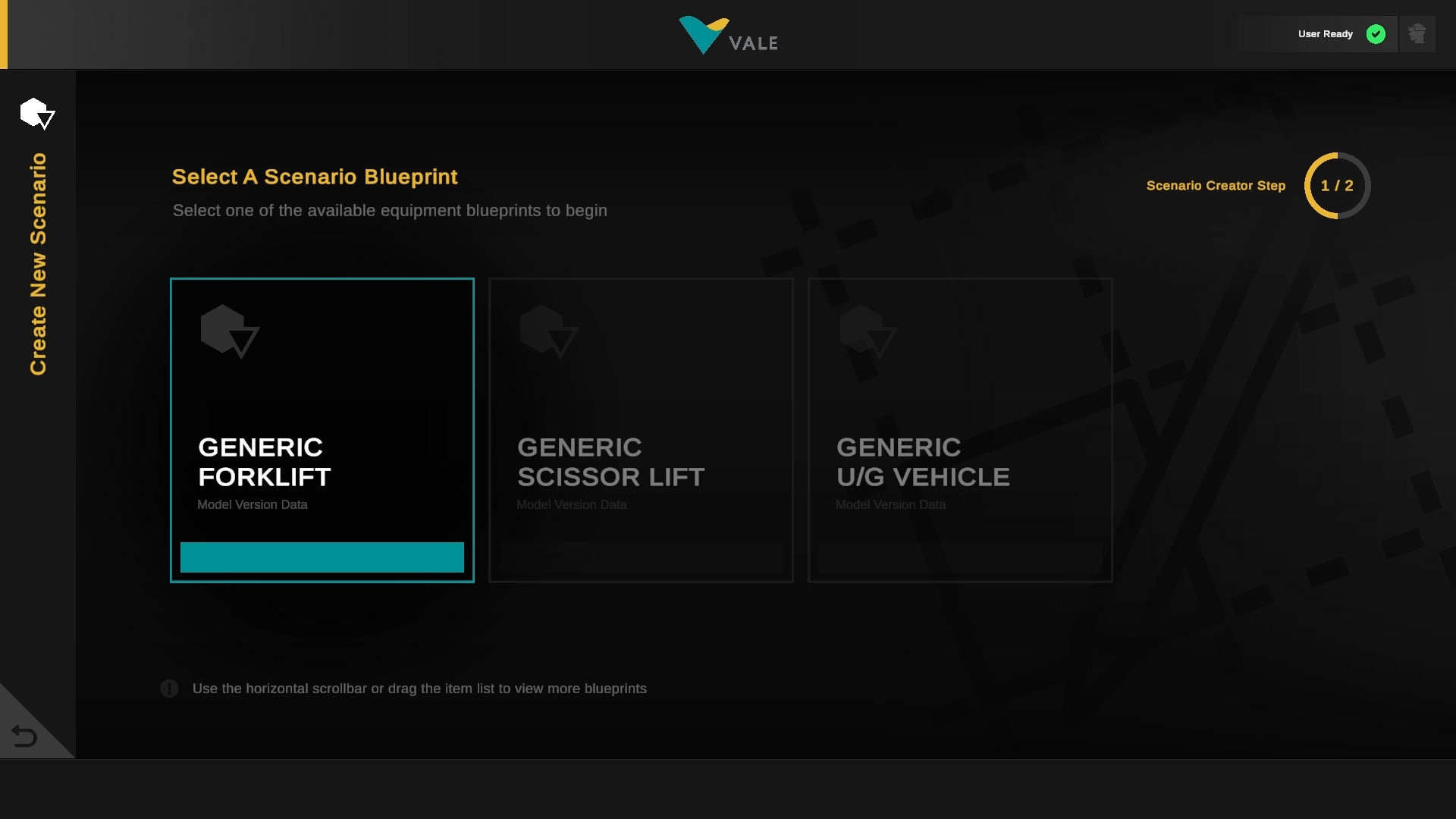

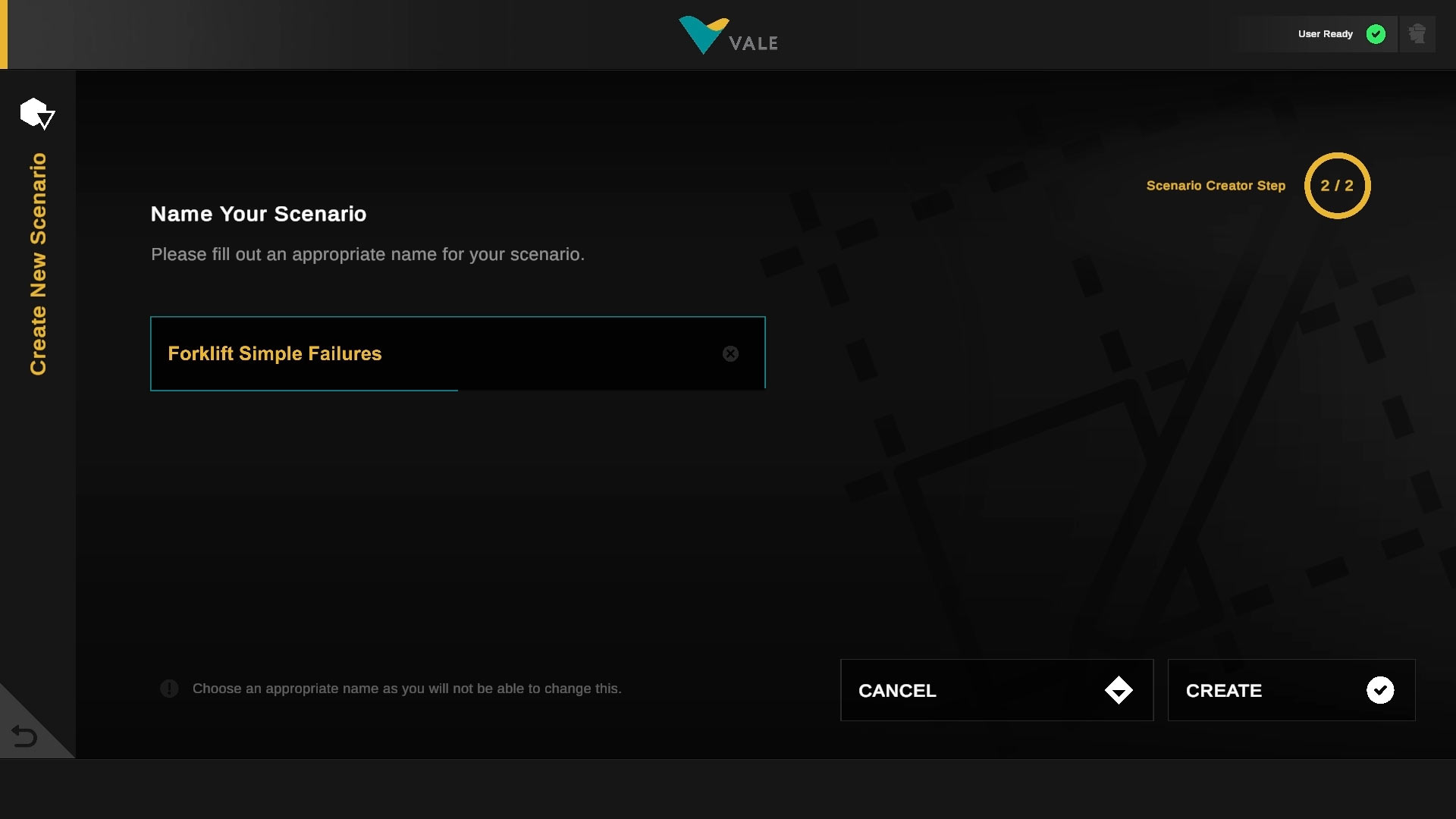

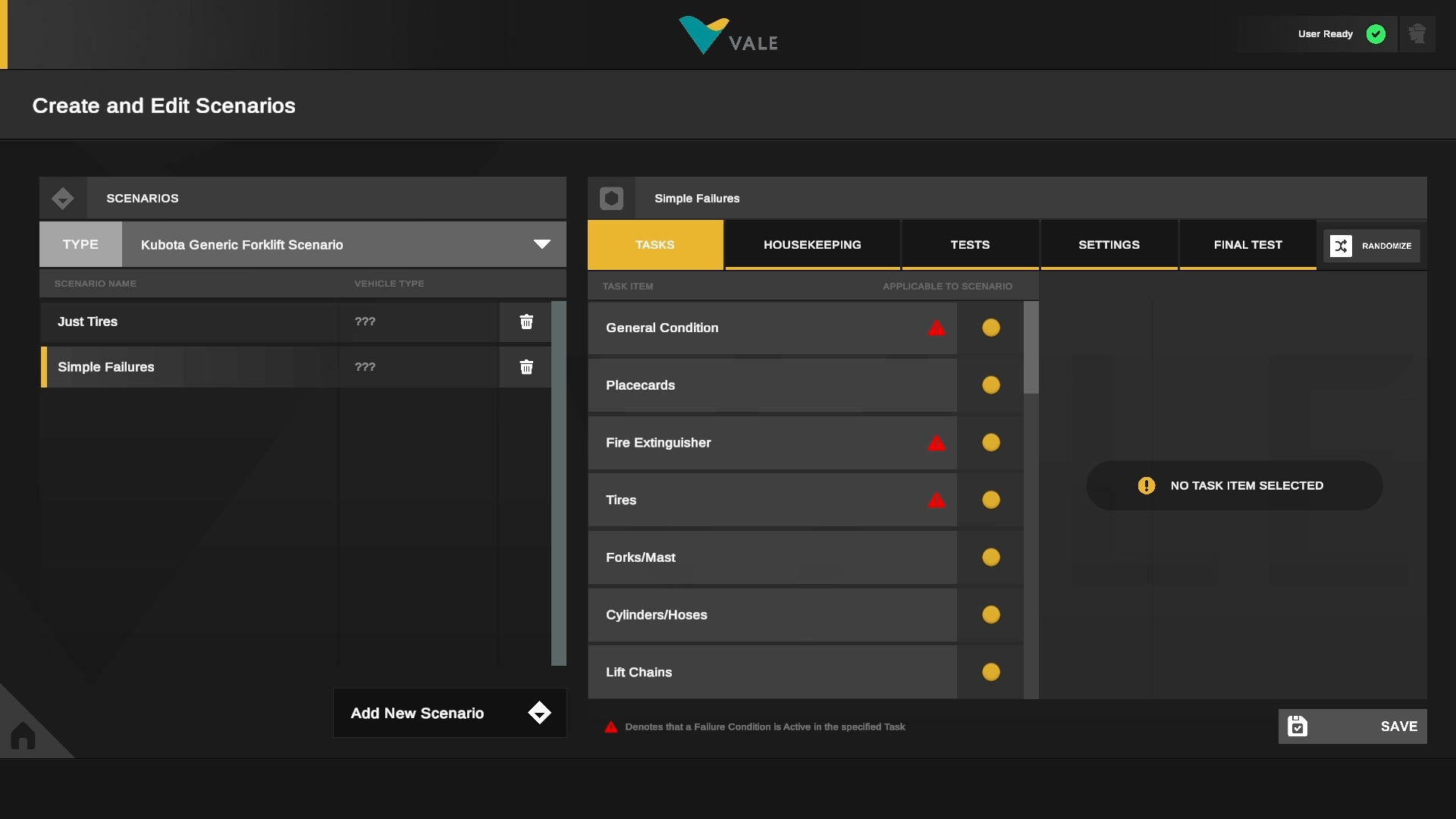

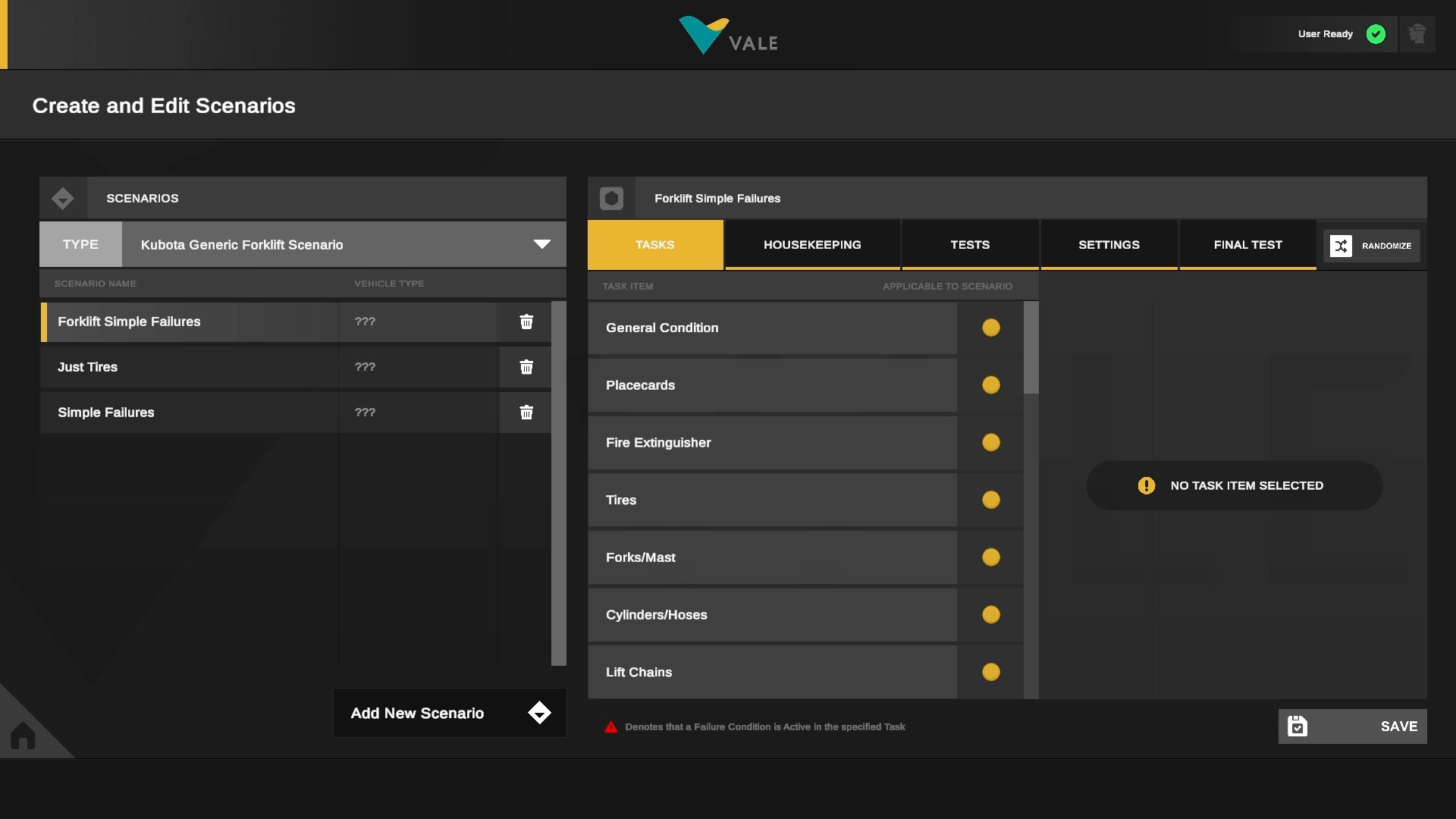

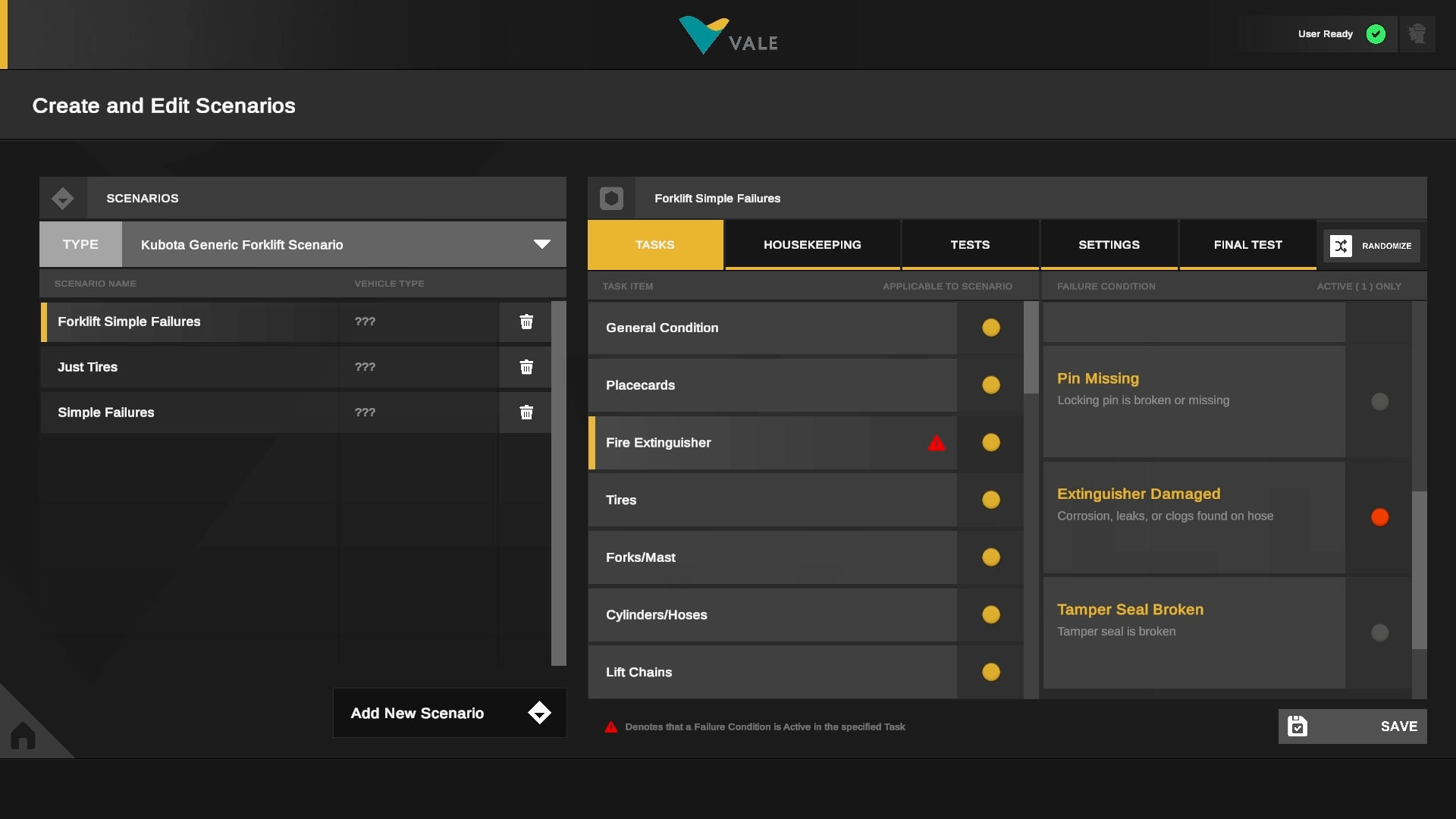

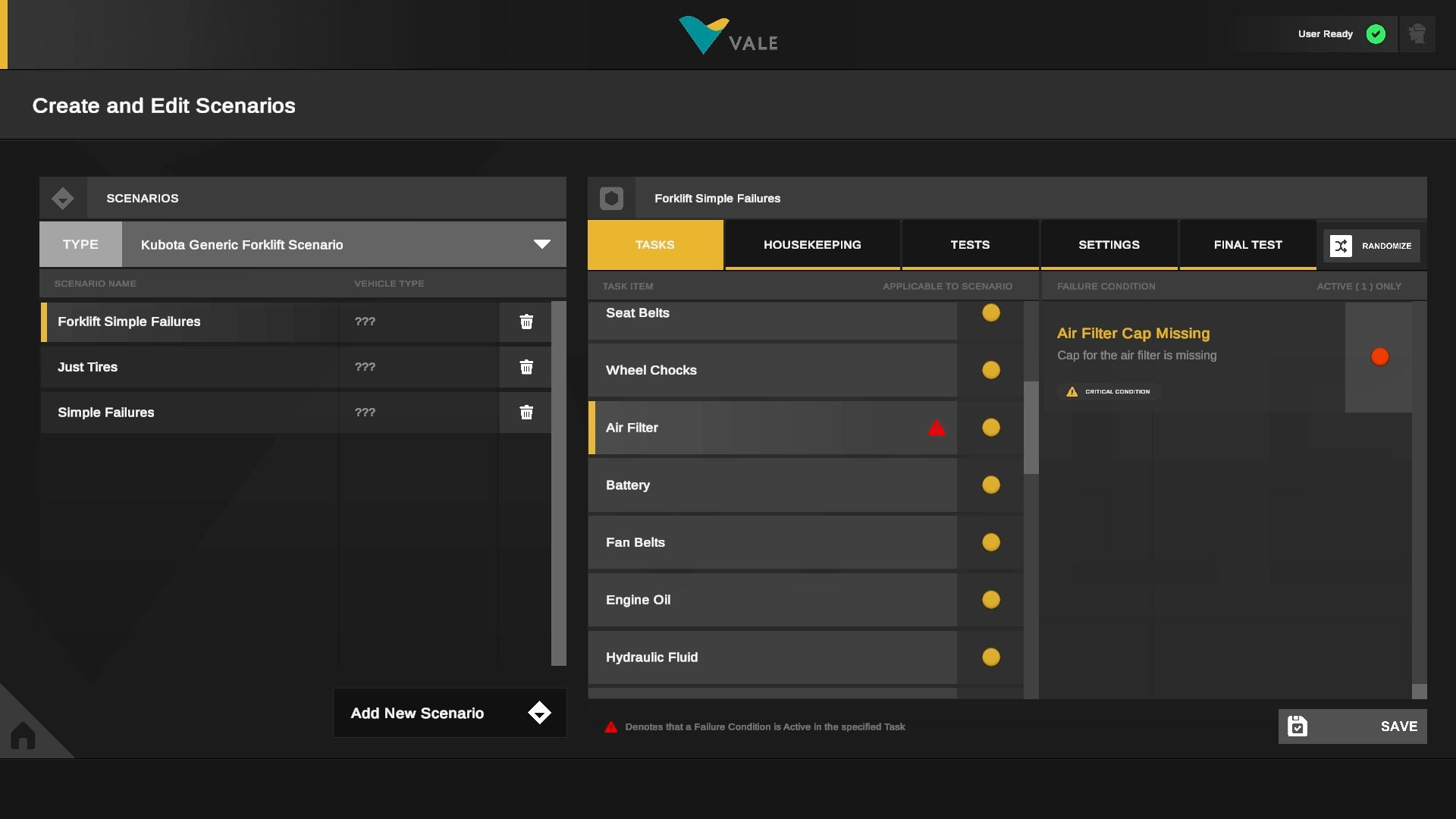

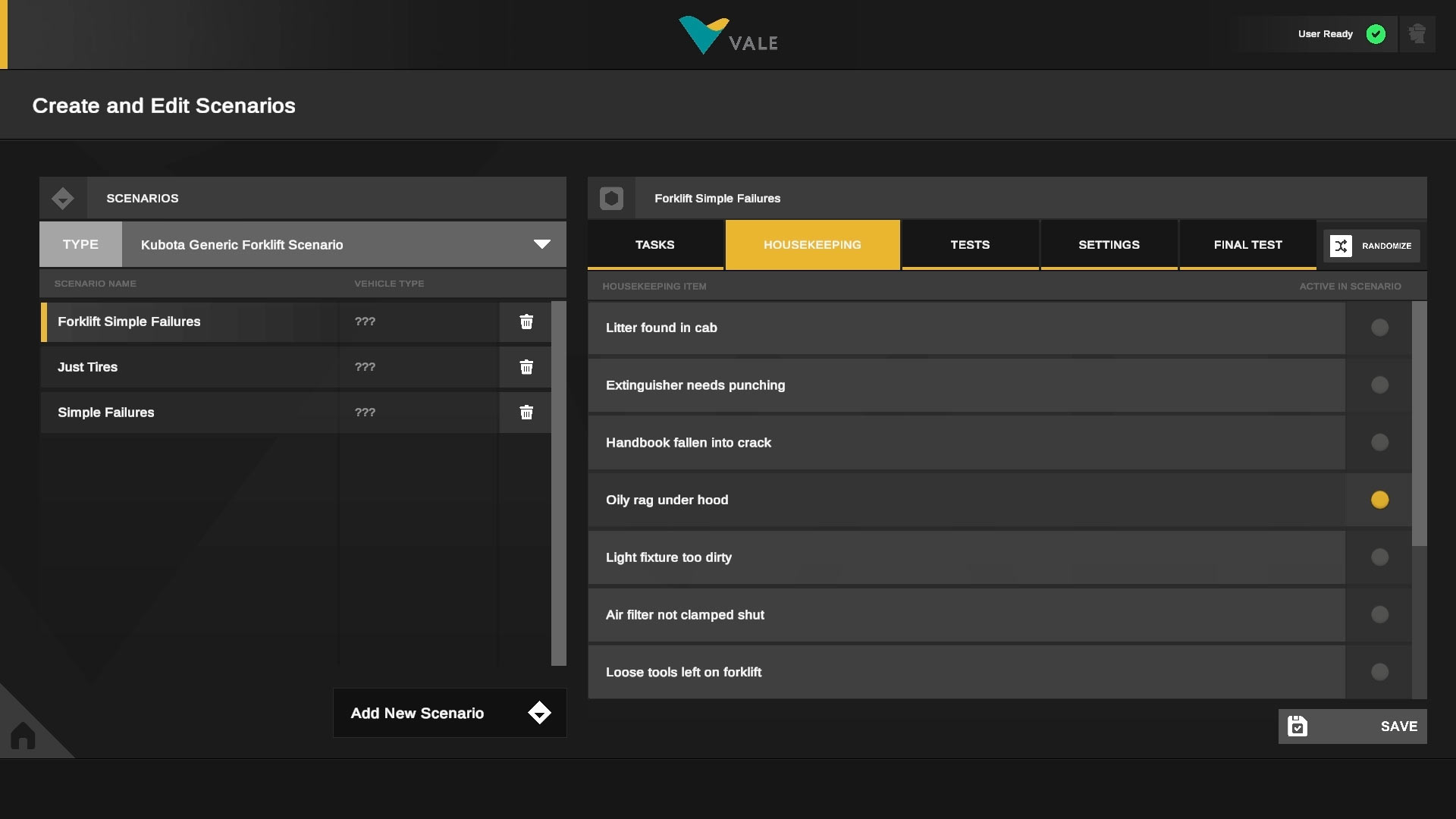

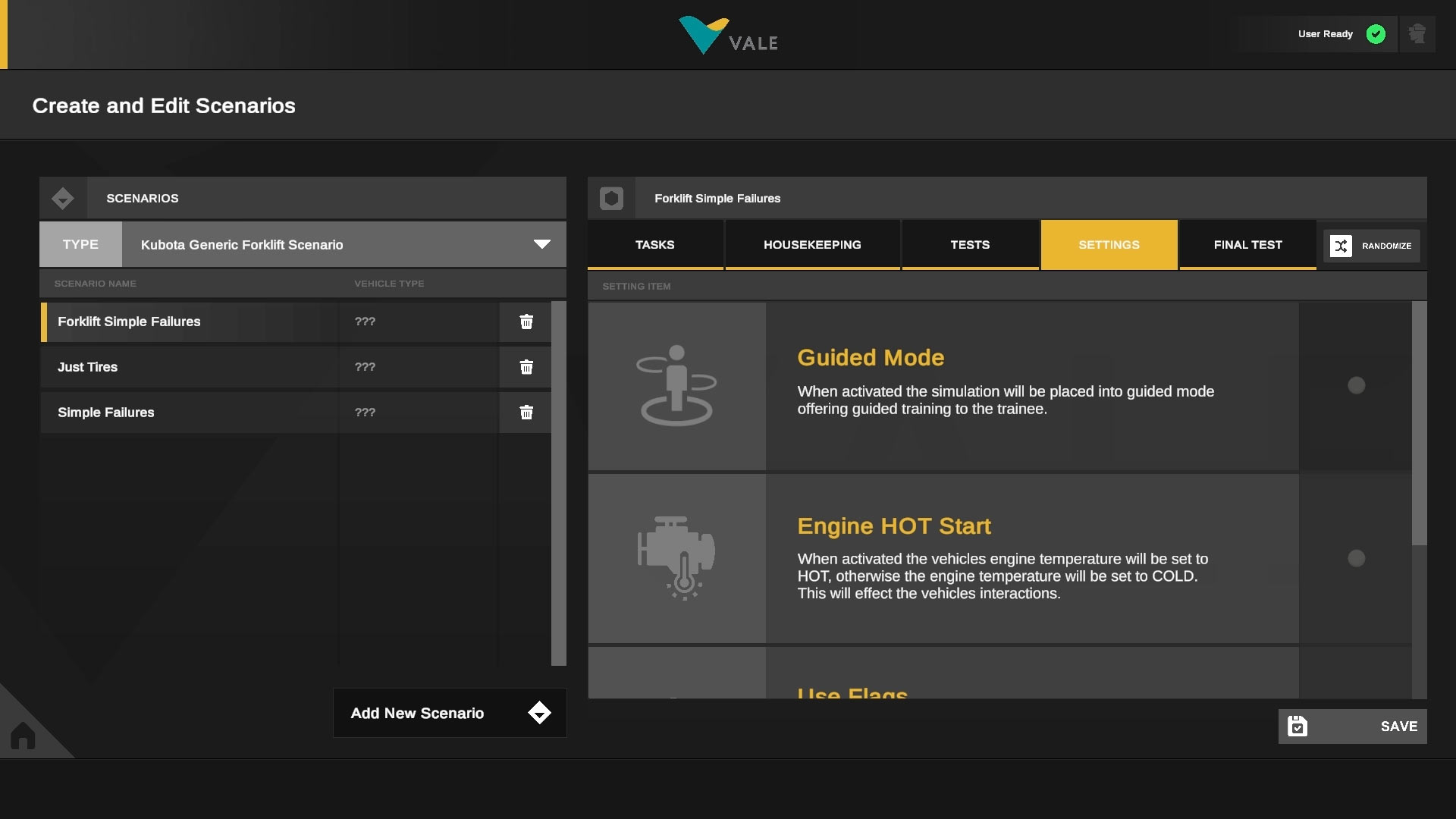

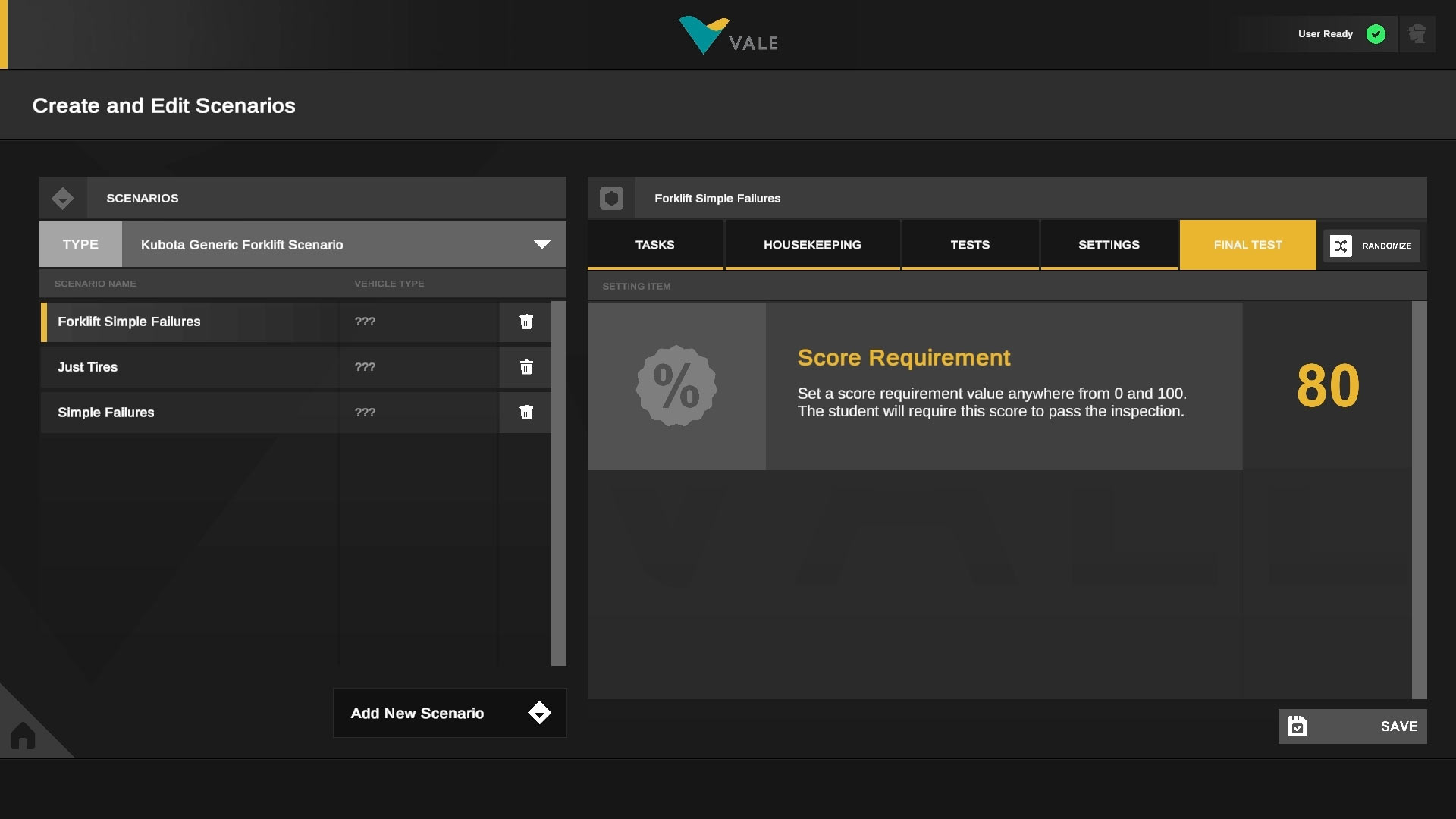

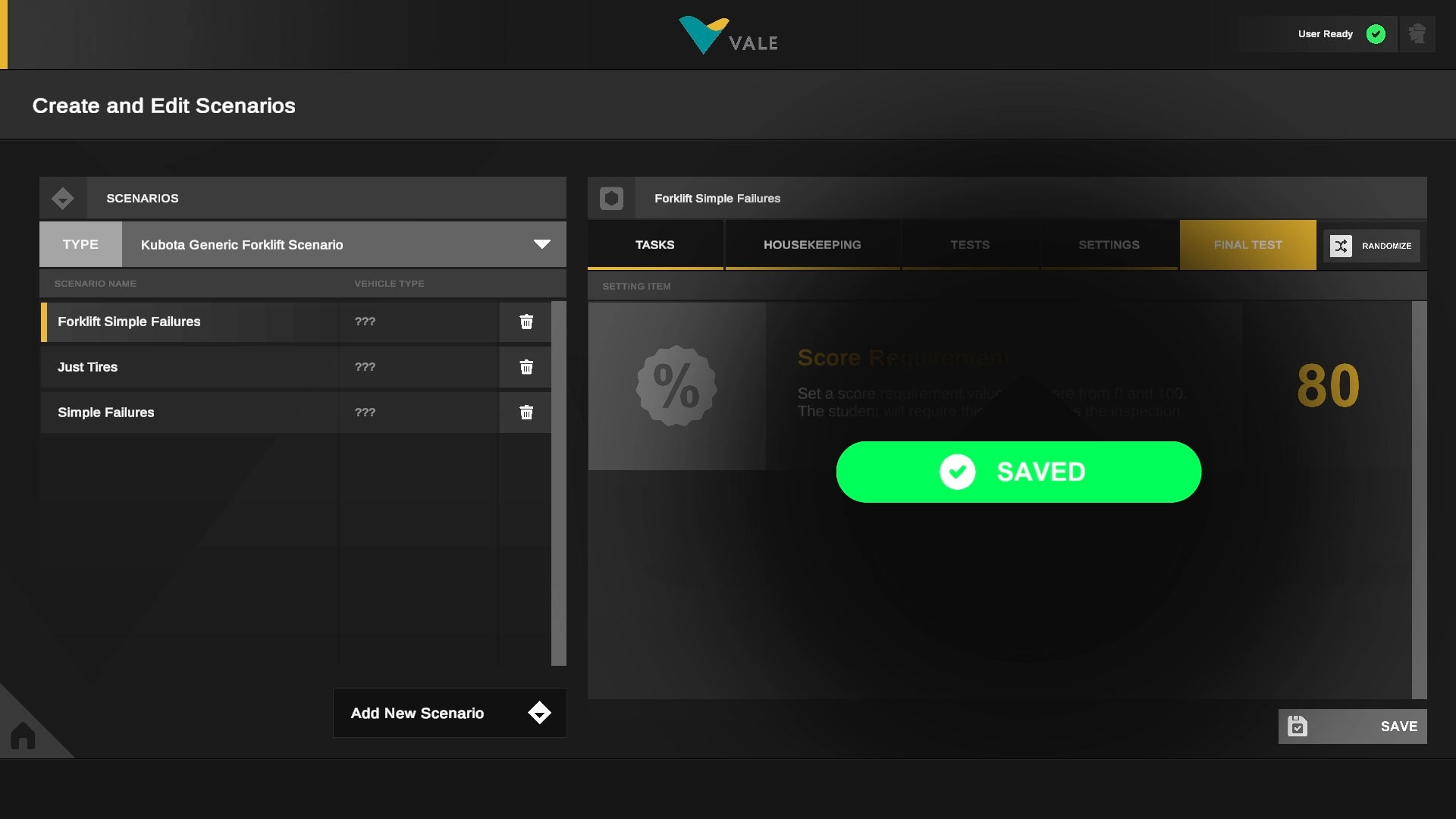

The program features a full training record management system for instructors to track their trainees. This includes: the ability to create and delete new students, load students for training, save and view student session reports, and the ability to export records for the purposes of importing into other internal management tools. However, our systems real power lies at the heart of the scenario creator. Instructors have full control over all the tasks, housekeeping items, and additional settings the equipment and pre-op tests require. For example, the forklift has over 90 different failure conditions that can be set by the instructor to give total control over how complex a scenario can be, ensuring that retraining is always new and refreshing.

Immersive Education for Student Engagement

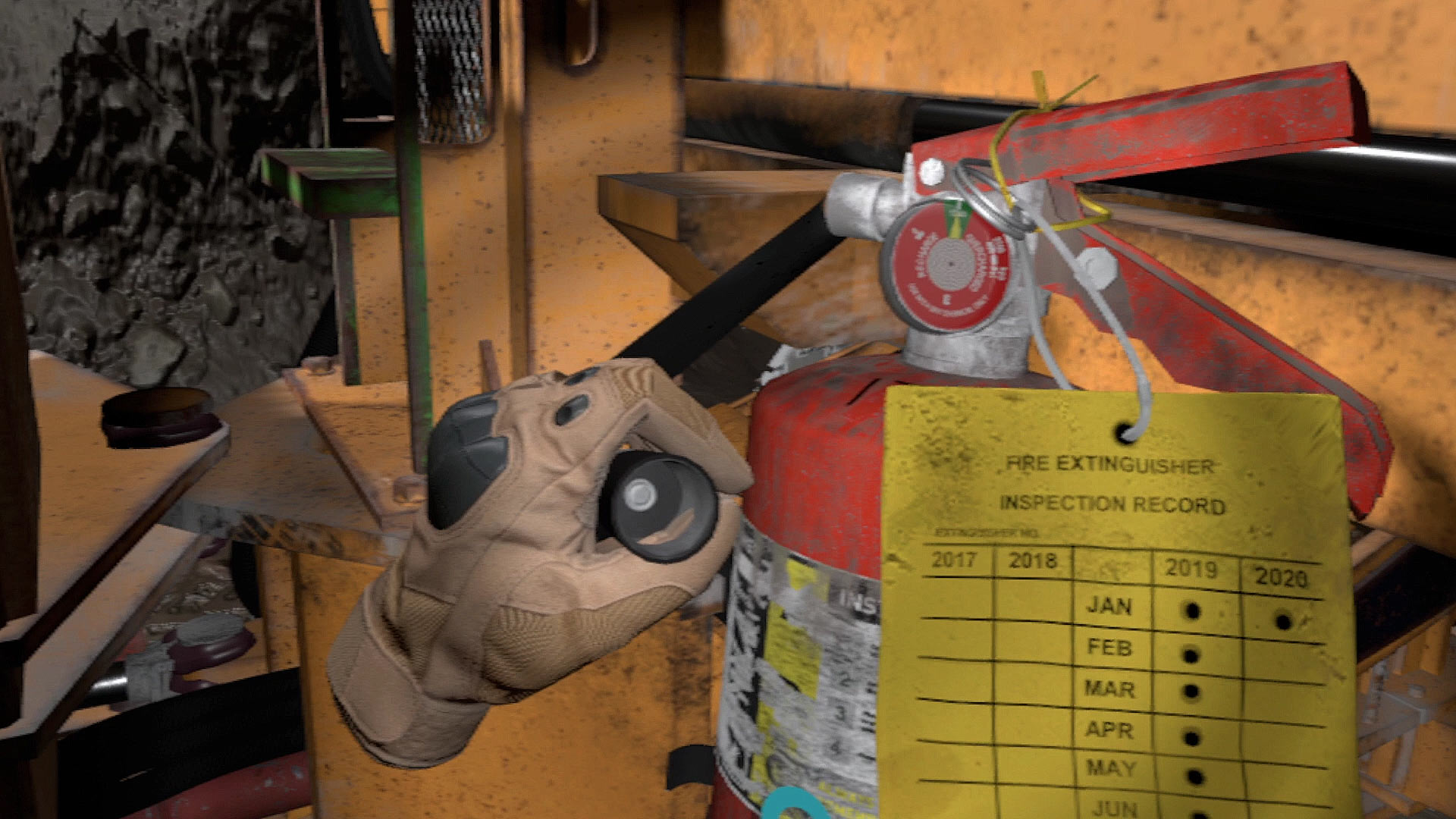

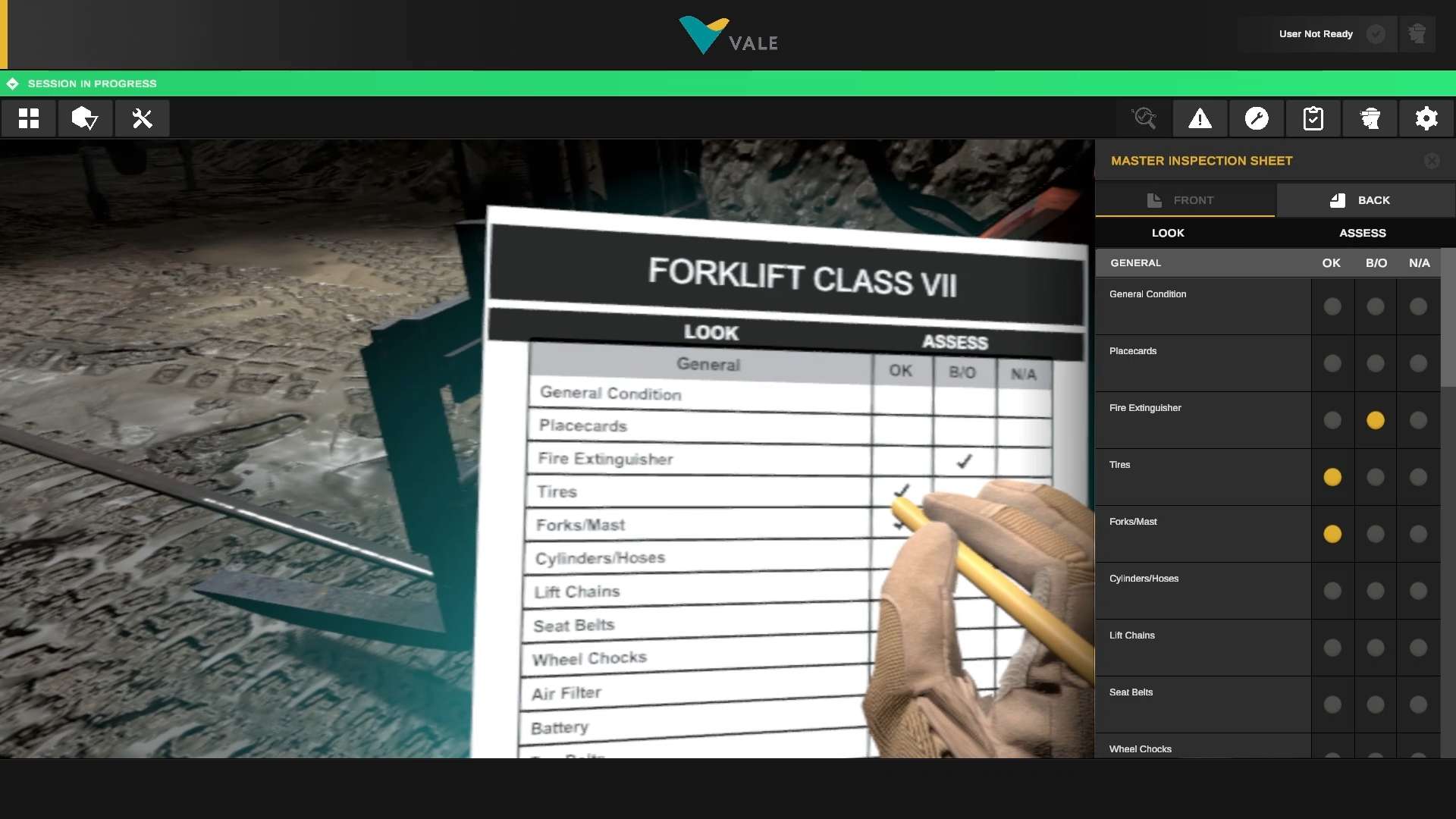

Our VR system allows for numerous interaction types that give the learners many ways to engage with real world counterparts. Students are able to interact with every critical part of the machine that is required to be inspected for mechanical performance, and safety of the student and all others. The student is placed into an immersive environment, alongside a detailed and accurate representation of the real-world equipment counterpart. Students will be tasked to perform walk around checks for housekeeping, and perform all the required operations in a simulated environment. This includes all the necessary steps to start the machine, as well as the operation of and the assessment of the machine. In all pre-op / post-op inspections, employees are given an equipment inspection sheet that is to be handed in to their supervisor at the end of the check. We recreated this process digitally, allowing the student to fill it out as they proceed through the simulated inspection.

Our Passion to Realistic Simulations

We pride ourselves on our dedication to realistic recreations. We meticulously work towards mirroring the real-world counterparts we are representing to ensure that all possible details are included, giving the simulation a true to life feel. Working with our clients, we are able to accurately replicate equipment and its operations to a very high degree of accuracy, with the added benefit of having in-house experts seasoned in mining and equipment operations to draw from.