Acid Train Car Loading

Applications are now closed.

Acid Train Car Loading

Smelter/sulphuric acid is a common chemical by-product of the smelting process. Given the risks associated with human exposure to a concentrated acid, it is carefully collected, stored and transported to ensure the health and safety of workers and surrounding communities. In partnership with Vale, NORCAT is seeking a potential technology solution for the mining industries current challenge of acid train car loading.

Deadline

Applications are closed.

Award

Fully funded PoC development & on-site testing / validation, and potential procurement if successful.

Challenge Description

In partnership with Vale, NORCAT is seeking a potential technology solution for the mining industries current challenge of Acid Train Car Loading. The ideal solution would look to remove the worker from harm's way. If this "ideal state" can not be achieved, then we would give priority to solutions that either reduce the likelihood of a safety incident occurring and/or reduces the impact/exposure should such an event occur.

Who should participate?

- In the ideation/research phase, a start-up, or a small to medium business.

- Based anywhere in the world, but need to be available to demonstrate and deploy your proof-of-concept solution in one of Vale’s operations located in the City of Greater Sudbury.

- Able to commit approximately 12 hours a week from April 19th, 2021 to August 20th, 2021 to work with Vale technical experts on developing, preparing and testing your proof-of-concept solution.

- Willing, able and excited by the potential of Vale issuing a purchase order deploy the solution broadly across their operations.

Opportunity

The company chosen for the test and Proof-of-Concept phase will be given a full budget to work and execute their trials as agreed upon by both parties. All start-ups will retain Intellectual Property Rights to anything created during this process. If successful, start-ups will have the opportunity to land a procurement deal with Vale and other Major Mining Companies.

Latest Updates

The challenge is now closed. NORCAT and Vale would like to thank everyone who applied.

Winners: - SK Godelius

Overview

Context

Smelter/sulphuric acid is a common chemical by-product of the smelting process. Given the risks associated with human exposure to a concentrated acid, it is carefully collected, stored and transported to ensure the health and safety of workers and surrounding communities. To clearly outline some of the key challenges related to acid management within our smelter, we have detailed some specific areas of concern where we believe there are opportunities to utilize technology solutions to mitigate them. Currently, within Vale's operations in Sudbury, several people are working in the acid loading facility on a given shift. On a typical day, 24-36 rail tank cars are loaded. The process, from start to finish, typically involves 3 people and takes 5 hours. It is not unusual for the team to be loading multiple rail tank cars (at various stages of the process) at the one time.

Problem Definition

Within Vale's acid loading facility, empty rail tank cars (leased by Vale, not Vale owned) are brought into the sulphuric acid loading station. Once parked and secured beneath the acid loading ramp/bridge, the fill valve on the top of the rail tank car is manually unlocked with pipe wrenches and other hand-tools (See Figure 1).

During this activity, accumulated pressure in the empty tank, developed naturally due to temperature differences between the atmosphere and the sealed tank, can lead to an unsuspecting worker getting "sprayed" by residual acid that is released as a result of de-pressurization. Although all workers are wearing personal protective equipment (see Figure 1.A), this creates the risk of exposure that can lead to acid burns.

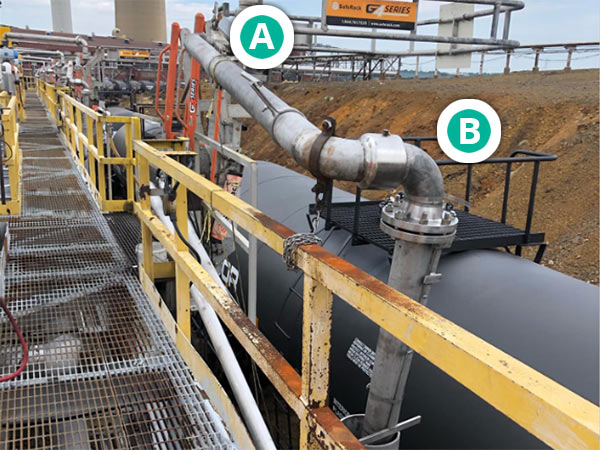

Once the valve is opened, the manual filling process is initiated. This involves transporting acid from a holding tank via a cantilevered piping infrastructure (see Figure 2) that is manually guided and routed into the fill valve via the overhead loading bridge/acid loading ramp. The fill pipe is guided into the valve atop the rail tank car (see Figure 1.B), but not locked or fastened.

With that, when the filling is started, problems have occurred due to splashing and overflowing that could cause harm to workers within the vicinity. It is important to note that there are multiple types of rail cars, with each having different couplings, fasteners and orientations requiring a flexible fill piping infrastructure that can be manipulated and guided into the rail tank car fill valve. The filling process is managed by a series of float valves installed in the rail tank car, which trigger the shutoff of the filling process when the tanks are full.

Once the rail tank car is full, the fill piping infrastructure is retracted and the valve atop of rail tank car is manually closed. At this time, to ensure proper closure, the tank is pressurized using compressed air to identify any leaks or broken seals before the rail tank car is permitted to leave the facility. This process involves the worker manually attaching a pressurized line into the rail tank car that could lead to potential exposure risks, especially if a seal or some part of the rail tank car has a leak.

Structure

Solution Development

As part of this open innovation call, Vale is seeking potential solutions that can be identified, developed and deployed as a Proof-of-Concept within a four (4) month time frame within its Sudbury operations. We are open to new ideas, concepts and technologies that will help our operations address this issue to ensure the on-going safety of our workforce.

Given the rail tank cars we utilize are widely used in heavy industry across Canada / US, there is a desire to share the validated solutions with our broader network, including our peers, suppliers and customers.

The ideal solution would look to remove the worker from harm's way. If this "ideal state" can not be achieved, then we would give priority to solutions that either reduce the likelihood of a safety incident occurring and/or reduces the impact/exposure should such an event occur.

Selected companies that are selected to participate in the Proof-of-Concept Boot Camp will be provided a Non-Disclosure Agreement to protect and validate your ownership of your intellectual property.

Judging and Awards

Selected ventures will be invited to participate in a web-meeting with Vale and NORCAT representatives to better understand the proposed solution and address any questions related to the requirements of the Proof-of-Concept Boot Camp.

- In the ideation/research phase, a start-up, or a small to medium business.

- Based anywhere in the world, but need to be available to demonstrate and deploy your proof-of-concept solution in one of Vale’s operations located in the City of Greater Sudbury.

- Able to commit approximately 12 hours a week from April 19th, 2021 to August 20th, 2021 to work with Vale technical experts on developing, preparing and testing your proof-of-concept solution.

- Willing, able and excited by the potential of Vale issuing a purchase order deploy the solution broadly across their operations

Timeline

-

Challenge Launch

Sept 21, 2020Applications for the NORCAT Open Innovation Challenge open September 21st, 2020. Ventures that believe they have a potential technology solution to one of the three challenges can apply below by completing the application form.

-

Application Deadline

October 16, 2020Applications must be submitted by October 16th, 2020. No late applications will be accepted. If you have any questions about your application, please reach out to openinnovation@norcat.org.

-

Successful Ventures Chosen

December 11, 2020Selected ventures will be invited to participate in a web-meeting with Vale and NORCAT representatives to better understand the proposed solution and address any questions related to the requirements of the Proof-of-Concept Boot Camp.

-

Proof-of-Concept Boot Camp

April 19, 2021Successful companies will connect with Vale technical experts, field resources and NORCAT Mentors to support the development of your Proof-of-Concept solution.

-

In-the-field Product Testing

August 23, 2021Once a successful Proof-of-Concept product is developed, ventures will commence in-the-field product testing within one of Vale’s Greater Sudbury operations to validate the effectiveness of the technology solution.

-

Potential Procurement & Rollout

September, 2021The purpose of the NORCAT Open Innovation Challenge aims to connect and broker a professional relationship between you, your venture and Vale that could lead to potential procurement opportunities within Vale and other mining companies.

Resources

Figure 1 - Top of tank car / valve

Figure 1.A - Worker wearing PPE; including an acid protective suit, rubber gloves, face shield, glasses with side shields, hearing protection and has a respirator and DAP on his person.

Figure 1.B - Cantelevered arm extended to prepare for filling. The end will go into the tank car once the lid is open.

Figure 2 - Cantilevered arm in its home position

Figure 2.A - Pivot point for arm to lift out of “drip collector” and turn perpendicular to the ramp to get into the tank filling position.

Figure 2.B - Cantelevered arm is home position, with filling end in pipe to “drip collector”.

FAQ

"The challenge under the Open Innovation Platform hosted by NORCAT in partnership with Vale has been very valuable for us. On the one hand, due to the depth of the problem posed, that is, not technically trivial and at the same time with great potential to be replicable far beyond the specific case. NORCAT has played a fundamental role in managing the relationship. It has helped a lot in defining the common path between Vale and SK Godelius. This involves dealing with multiple dimensions, operational, innovation and engineering, which often have different urgencies and priorities. This has been especially important in times of pandemic, where an important part of the interaction has had to be virtual. In short, NORCAT has made a decisive contribution to the viability of our project."

- Fernando Bracco, CEO and Founder, SK Godelius